Managing water is perhaps the most challenging aspect in the digging process of many mines. At a plant that harvests doré bars, or semi-pure alloys of gold and silver, in the Mexican state of Chihuahua, the mix of exposed rock and water presents an evolving challenge workers and engineers must contend with to ensure smooth operations.

While the facility started out with pumps from different manufacturers, over the last 10 years it has turned entirely to Tsurumi pumps to establish a reliable and cost-effective dewatering system. It’s a tall order: the system must be able to move large amounts of mud, slurry and gravel continuously, 24 hours a day. Six of the newest additions to the system are high-volume, three-phase dewatering GSZ-150-4 pumps.

“Crucial to the mine’s choice of the GSZ pumps was their flow capacity, which is powerful enough for the requirements of its operations,” said Larry De la Torre, president of Clowe & Cowan, a Tsurumi distributor in El Paso, Texas. “Representatives from the mine told us they needed pumps to draw a lot of water quickly, that’s why we recommended such powerful pumps. There are similar pumps from other brands out there, but only Tsurumi combines quality, reliability and reasonable prices, they said.”

Built to lastimage

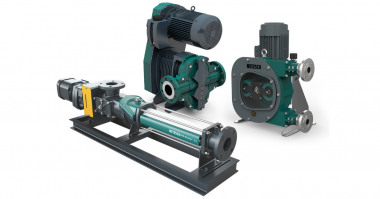

A robust design is one of the most crucial aspects of pumps operating in a mining dewatering system. Mines are tough environments that combine abrasive elements with heavy machinery, making wear resistance crucial. The GSZ series is one of the most formidable high-volume submersible pumps available, with capabilities to pump up to 5,000 GPM. With impeller materials of high chrome and stainless steel, the GSZ series tackles the most aggressive dewatering applications.

“Tsurumi’s products are known for their strength and quality, and that’s exactly what the managers of the Chihuahua mine were looking for,” said Vicente Marín, sales manager at Representaciones Industriales Marin (RIMA), a Tsurumi distributor in Mexico. “With a reputation for great durability, some of its pumps can even be found working today after more than 25 years active service.”

Today the Chihuahua plant has about 80 Tsurumi pumps in operation. In addition to the six GSZ-150-4 models, the facility employs dozens of pumps from the LH (medium to high flows at high head) and LHW Series (extremely high head capabilities), including the LH411, LH422, LH6110, LH645, LH25.5W and LH430W.

To watch a video of a GSZ-150-4 being led into the mine, click here. To see a video of its water discharge, click here.

For more information on Tsurumi’s GSZ-150-4 pumps, click here.

Comments