Some companies have a policy of torqueing motor hold down bolts to set prescribed value. While this may be a regulation in some industries, or required on specific types of machines, it really has little to do with the quality, accuracy, or repeatability of alignment, if the alignment is done properly.

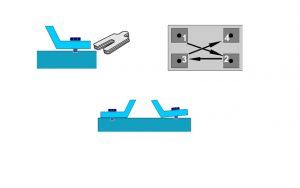

Most millwrights may disagree. This is because they have seen changes in the alignment values during the tightening process, and attribute it to bolt torque. But the real reason the values change is because of uncorrected soft foot.

If a cast iron motor foot sits on a stainless steel shim, which sits on a steel base – high torque tightening with a wrench WILL NOT cause the foot to get any closer to the base. To do so one of two things must happen:

- Voids due to a bent foot or warped base, or contaminants such as dirt, paint, rust, or some other foreign material MUST BE between the foot, shims, and base.

- The stainless steel shim must flow, and become thinner.

#1 happens frequently. Most mechanics know the crackling sound it makes as the foreign materials are broken apart due to the force imparted by tightening. It also puts minute dents in the shims, feet, and base.

#2 is pretty much impossible, because either the bolt will shear from such a force, or the threads would pull out, long before the stainless steel shim gets any thinner.

So, the changes in alignment that happen while the bolts are being tightened are from soft foot, or foreign material under the feet, not from differing torque values.

Make sure the base, shims, and motor feet are clean. Deburred is even better. Correct for soft foot. Use clean shims.

If you use a torque wrench, that’s fine. But just remember the wrench won’t get the motor feet any closer to the base than the thickness of the shims, no matter how hard you pull on a wrench!

Comments